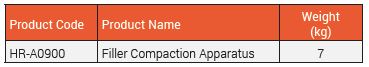

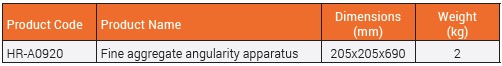

Filler Compaction Apparatus

General Features:

Filler Compaction Apparatus is used for the determination of the voids content of dry compacted filler.

The apparatus consists of three parts:

- cylinder having inside diameter 25.4 mm;

- plunger freely sliding into the cylinder with max. lateral play of 0.20 ± 0.05 mm;

- four columns and metallic base holding the whole, size 100×150 mm.

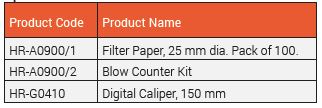

To perform the test a measuring device (vernier caliper with 0.01 mm accuracy) and 25 mm dia. Filter Paper are required and should be ordered separately.

It can be fit with a Blow Counter Kit, should be ordered separately.

Standards:

EN 1097-4, BS 812

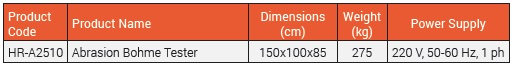

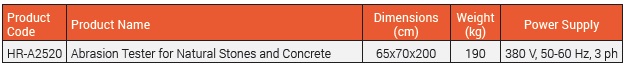

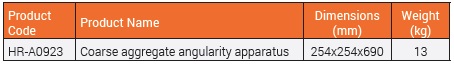

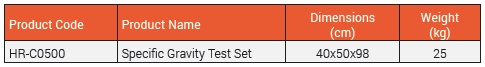

Technical Specifications:

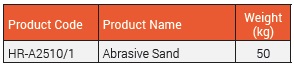

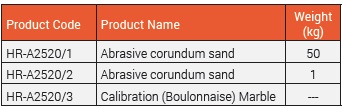

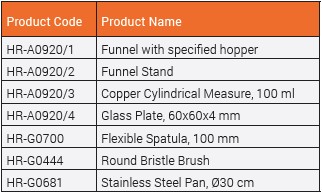

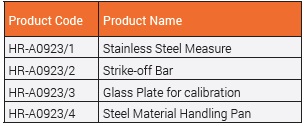

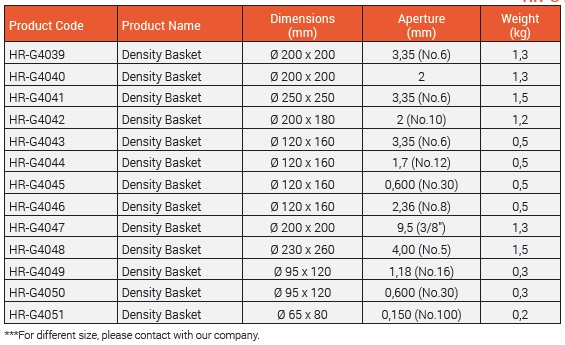

Accessories / Spare Parts:

%20SET.jpg)